How to Ensure Your Water Mist System Operates at Peak Efficiency: 7 Maintenance Tips for 2024

Water Mist Systems, 7 Maintenance Tips for 2024

Water mist systems have become a critical component in modern fire protection strategies, offering a highly effective means of suppressing fires while minimizing water damage. However, like any sophisticated technology, these systems require regular maintenance to function correctly and reliably. This article delves into the importance of maintaining water mist systems, the key maintenance procedures, common issues, and why adhering to a maintenance schedule is crucial.

Key Takeaways

- Optimal Performance: Regular maintenance ensures that water mist systems operate at peak efficiency and effectiveness.

- Reliability: Adhering to maintenance schedules enhances the reliability of the system in case of a fire emergency.

- Common Issues: Identifying and addressing common issues during maintenance can prevent system failures and costly repairs.

Understanding Water Mist Systems

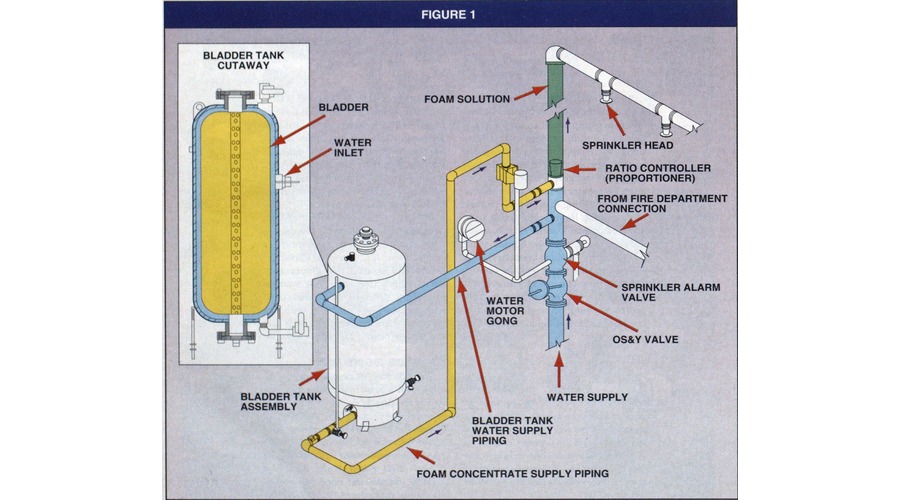

Water mist systems utilize fine water sprays to control, suppress, or extinguish fires. These systems are designed to cool the flames and surrounding gases, displace oxygen, and reduce radiant heat, making them highly effective for various fire scenarios. The fine mist allows for rapid cooling and minimal water damage, making it ideal for areas where traditional sprinkler systems might cause significant harm.

The Importance of Regular Maintenance

Ensuring Optimal Performance

Regular maintenance is vital for ensuring that water mist systems perform optimally. Over time, components can wear out, become clogged, or suffer from other forms of degradation. Maintenance activities such as inspections, testing, and cleaning help keep the system in top condition, ensuring it can respond effectively during a fire.

Enhancing System Reliability

The reliability of a water mist system depends heavily on its maintenance. A poorly maintained system may fail to activate or perform inadequately, potentially leading to disastrous consequences. Regular checks and servicing help identify and rectify potential issues before they become critical, thereby enhancing the system’s reliability.

Compliance with Standards

Adhering to maintenance schedules is not only a best practice but often a regulatory requirement. Standards such as NFPA 15 outline specific guidelines for the maintenance of water spray fixed systems, which can include water mist systems. Compliance with these standards ensures that the system meets all necessary safety and operational criteria.

Key Maintenance Procedures

Regular Inspections

Regular inspections are the cornerstone of effective maintenance. These inspections should be comprehensive, covering all components of the system, including nozzles, pipes, pumps, and control panels. Inspections help identify wear and tear, corrosion, blockages, and other issues that could impair the system’s functionality.

Testing and Drills

Periodic testing is essential to verify that the system operates as intended. This includes functional tests of the pumps, control valves, and alarm systems. Conducting regular fire drills can also help ensure that personnel are familiar with the system’s operation and can respond appropriately in an emergency.

Cleaning and Flushing

Over time, debris and sediment can accumulate in the system’s pipes and nozzles, potentially obstructing the flow of water mist. Regular cleaning and flushing of the system help prevent these blockages, ensuring that the mist can be effectively distributed when needed.

Component Replacement

Certain components of the water mist system, such as seals and gaskets, may need to be replaced periodically. Regular maintenance schedules should include checks for these wear-prone parts and their timely replacement to prevent leaks and other malfunctions.

Common Issues and How to Address Them

Clogged Nozzles

Clogged nozzles are a common issue that can significantly impair the effectiveness of a water mist system. Regular cleaning and the use of filtered water can help prevent clogs. If a nozzle becomes clogged, it should be cleaned or replaced immediately.

Corrosion

Corrosion can affect the pipes and other metal components of the system, leading to leaks and reduced water flow. Regular inspections can help detect early signs of corrosion, and using corrosion-resistant materials can mitigate this issue.

Pump Failures

The pump is a critical component of the water mist system, responsible for delivering the necessary pressure to create the fine mist. Regular testing and maintenance of the pump are essential to ensure its reliability. Any signs of wear or malfunction should be addressed promptly.

Electrical Issues

Water mist systems often rely on electronic control panels and sensors. Electrical issues, such as faulty wiring or power supply problems, can prevent the system from activating. Regular checks of the electrical components and backup power sources can help ensure the system’s readiness.

The Role of Professional Maintenance Services

While some maintenance tasks can be performed by in-house personnel, others require the expertise of professional maintenance services. These professionals have the knowledge and tools to conduct thorough inspections, testing, and repairs. Engaging a professional service can provide peace of mind that the system is maintained to the highest standards.

Water Mist System Maintenance FAQS

Related Articles

Ready to ensure your water mist system operates at peak efficiency?

Regular maintenance of water mist systems is not just a regulatory requirement but a critical practice to ensure their optimal performance and reliability. By adhering to maintenance schedules, conducting thorough inspections, and addressing common issues, you can ensure that your water mist system is ready to protect lives and property in the event of a fire.

Whether you want to request a quote, schedule a consultation, or have questions, we’re here to help! Send us a email, call us at, or fill out our form for a quick response. Protect your property with confidence—get in touch today!