Industrial Fire Protection in Industrial and Manufacturing Settings

Can you imagine the consequences of cutting corners when it comes to industrial fire protection?

Think about it: Industrial and manufacturing environments are like a high-stakes chessboard, filled with unique fire hazards. A single spark in the wrong place turns the risk of a devastating fire into a ticking time bomb!

The numbers don’t lie.

Recent NFPA data shows that industrial fires cause $1.5 billion in property damage annually. And what about human injuries and loss of life and the families who’ll lose their loved ones?

That’s why having proper industrial fire safety strategies is so important.

The Most Common Industrial Fire Hazards

While some industrial fire hazards are impossible to miss, others lurk in the background, quietly growing until a small spark triggers a full-blown fire.

Here are the most common culprits:

- Combustible dust

- Chemical spills

- Overheating equipment

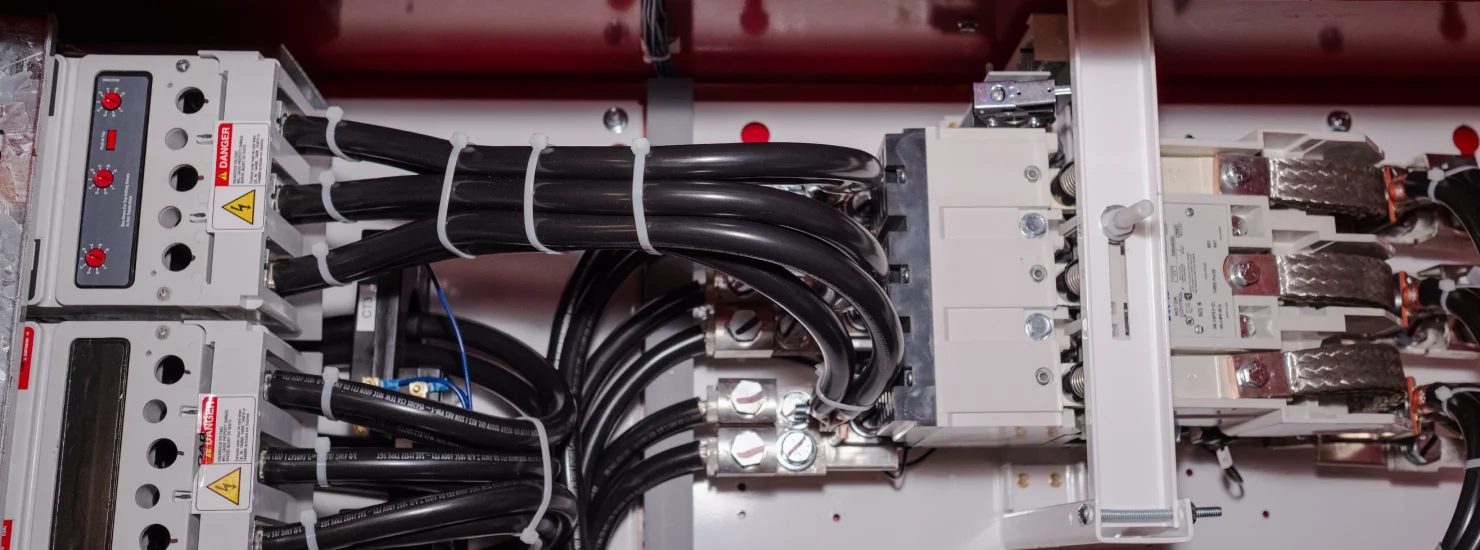

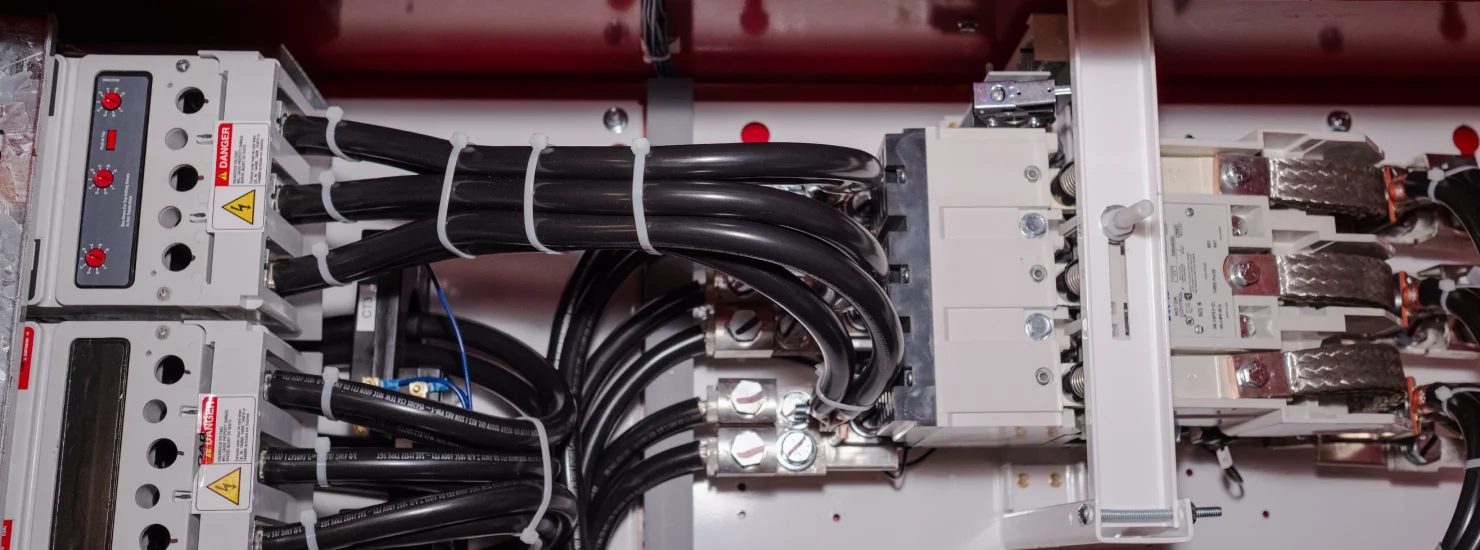

- Electrical malfunctions

- Flammable gases and liquids

- Poor storage of waste and combustible materials

- Cooking equipment

- Hot work equipment, such as torches, burners, and soldering irons

- Exposure fires

The Leading Industrial Fire Protection Strategies

You can’t address industrial fire protection by half-heartedly slapping a few fire extinguishers on the walls and calling it a day! It doesn’t work like that.

To protect your facility, consider the following strategies.

Install Specialized Fire Suppression Systems

Not all fires are created equal, which means you can’t use the same systems to put them out. Sure, water-based sprinklers might work in some cases. But what if you’re dealing with chemicals or electrical equipment?

That’s where specialized systems come in.

- Foam-based systems are ideal for flammable liquids.

- Dry chemical systems work wonders on combustible materials.

- Clean agent systems are perfect for protecting sensitive equipment.

The key is to tailor your fire suppression system to the unique needs of your facility.

Upgrade Your Industrial Fire Alarm Systems

Time is the one thing standing between a small spark and a full-blown disaster. And that’s exactly what modern fire alarm systems buy you.

Remember the traditional industrial fire alarm systems made up of bells and whistles? Well, thanks to modern technology such as artificial intelligence (AI) and the Internet of Things (IoT), these alarm systems have been upgraded.

Modern alarm systems are smarter with razor-sharp accuracy. This means enhanced fire detection accuracy and alerts, reduced false fire alarms, and predictive maintenance.

Stay on Top of Maintenance and Inspections

Even the best fire safety equipment is useless if you fail to maintain it properly.

Fortunately, NFPA 25 and NFPA 27 non-negotiable regulations clearly outline how to maintain and inspect these systems. Remember, though, only certified technicians should handle maintenance and repairs. Cutting corners here is a risk you can’t afford to take.

Train Your Team and Plan for Emergencies

Where others see employees, you should see a critical asset in industrial fire protection. But even the best team can falter without the right training and tools.

So:

- Bring in certified fire safety experts for hands-on training.

- Teach employees how to properly use fire extinguishers, respond to alarms, and evacuate safely.

- Regularly run fire drills to keep everyone on the same page.

- Develop clear, actionable emergency plans to reduce panic and confusion during a real fire.

Create Fire Barriers and Compartments in Your Facility

Never expect a fire to play fair. It’ll always go for maximum damage and spread fast, especially if your facility is packed with multiple industrial fire hazards.

The solution?

Fight back with fire barriers and compartments. These are your first line of defense, containing fires and stopping them from turning into facility-wide disasters.

Plus, they create safe zones, buying your team precious time to evacuate and giving emergency crews the space they need to help.

The Cost of Industrial Fire Protection Non-Compliance

If you’re thinking of skipping fire safety regulations, think again. Organizations like the NFPA and OSHA don’t hand out guidelines for fun — they exist to help prevent disasters.

Ignoring industrial fire protection can lead to:

- Severe injuries and loss of human life

- Hefty regulatory fines and penalties

- Massive destruction of property

- Loss of livelihoods

- Legal action

- Increased insurance premiums

- Reputational damage

- Significant operational disruptions

For instance, the TPC Group chemical plant in Port Neches, Texas, was fined a whopping $100 million for ignoring “popcorn polymer,” a dangerous material that built up and caused an explosion, injuring workers, damaging property, and causing mandatory evacuations in the area.

This is just one example underscoring the importance of following fire safety regulations and investing in proper industrial fire safety equipment.

Industrial Fire Safety System FAQS

Secure Your Facility With Kord Fire Protection

Industrial fire protection is one of those things you can’t afford to gamble with. Not when lives, livelihoods, families, communities, and your business risk unimaginable loss. The good news is, with Kord Fire Protection, you don’t have to.

We specialize in keeping industrial environments safe with tailored fire protection solutions. Whether you need expert guidance, advanced fire suppression systems, or employee training, we’re here to help.

Don’t wait for that spark. Contact us today for a consultation on how to secure your facility.

Stay Ahead with the Latest in Industrial Fire Safety Systems

Join our newsletter to get expert tips, compliance updates, and new innovations in industrial fire safety systems—delivered straight to your inbox.